Crane Insulation Monitoring

The application of cranes in economic activities is ubiquitous, and ensuring the safety of cranes during use has increasingly attracted the attention of safety production departments. Regular insulation resistance testing and maintenance of cranes have also become an important way to ensure their safe operation.

Generally speaking, cranes include gantry cranes, tower cranes (commonly known as "tower cranes"), mobile cranes, and gantry cranes. For the above types of cranes, the General Administration of Quality Supervision, Inspection and Quarantine of China has also issued the "Supervision and Inspection Regulations for Cranes" to standardize the insulation testing of cranes. It is required that when using a rated voltage less than 500V for testing, the insulation resistance of the electrical circuit to ground should generally exceed 0.8M Ω, and when in a humid environment, the insulation resistance should exceed 0.4M Ω. Therefore, the current insulation resistance testing of cranes mainly uses traditional manual DC500 shaking meters for related monitoring work. Due to the large number of crane motors and complex testing processes, the current working environment is complex. In addition, during testing, the power must be turned off, and manual measurement of the motor winding phases must be carried out through a shaking table, which is time-consuming, affects production, and may result in errors during the measurement process, posing significant operational risks. Therefore, there is an urgent need for new technologies and more intelligent insulation resistance detection methods to improve the existing time-consuming and laborious traditional detection methods.

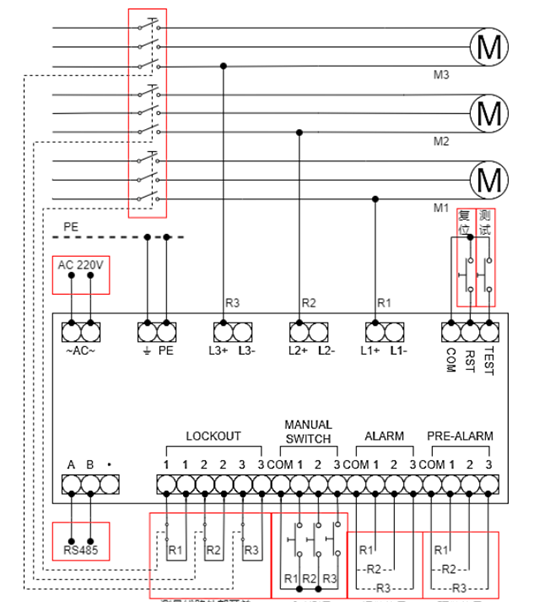

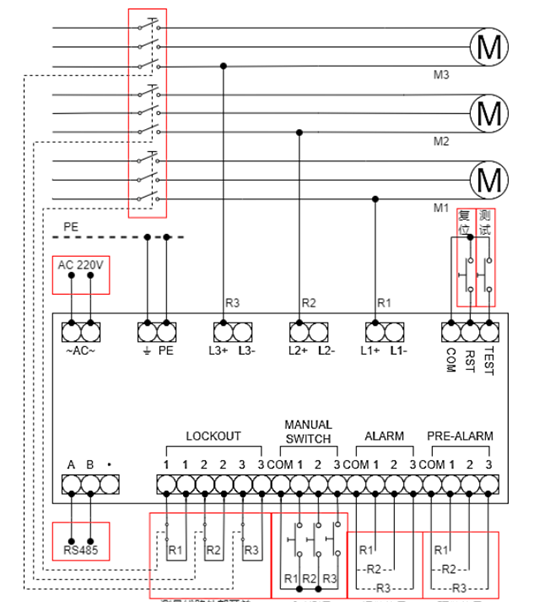

After years of improvement and technological optimization of insulation monitoring products, Sikcon has successfully developed multiple targeted intelligent insulation monitoring devices for cranes, including SKIM600M and SKIM24-3C insulation monitoring devices. Among them, SKIM600M is a single channel insulation detection device that can only perform insulation monitoring on one circuit of the crane; SKIM24-3C is capable of insulation monitoring at three points, including the trolley to hook, hook to crossbeam, and crossbeam to motor of the crane. In the product development process, SKIM24-3C fully considers the pain points of crane insulation monitoring. As it is real-time monitoring, we have designed the monitoring voltage from 500V DC to 24V DC, which is safer. In addition, adaptive development has been carried out in terms of product appearance and size, product performance display, intelligent application, and monitoring technology capabilities. The relevant features include the following:

1. Compact Appearance Structure

Due to the functional requirements of the equipment and insufficient extra space, cranes have strict requirements for the size of additional installation and supporting detection equipment. Therefore, there are strict requirements for the size of intelligent insulation monitoring instruments installed in the supporting installation. Therefore, Sikcon's SKIM24-3C intelligent insulation monitoring device for cranes is 50% smaller in size and has a more convenient installation aperture compared to traditional insulation monitoring devices in the market.

2. Real time monitoring of multiple motors by a single device at once

Cranes are generally composed of multiple electric motors, and insulation monitoring of each motor is required in confined spaces. This not only requires strict volume requirements for insulation monitoring instruments, but also demands insulation monitoring technology. Therefore, the SKIM24-3C crane specific intelligent insulation monitoring device enables online insulation monitoring of three parts of the crane on a single device simultaneously. Not only can it save installation space, but it also achieves cost advantages.

2. Simultaneously achieve insulation monitoring in three locations

SKIM24-3C is capable of insulation monitoring at three points, including the trolley to hook, hook to crossbeam, and crossbeam to motor of the crane. One device can simultaneously meet the monitoring needs of three locations.

3. Automatic monitoring, reducing equipment failure risks, and ensuring personnel safety

SKIM24-3 intelligent insulation monitoring device can perform automatic monitoring according to the power status. When the power is turned off, the intelligent insulation monitoring device automatically starts to monitor the insulation resistance; When the power is turned on, the insulation monitoring device will automatically stop insulation monitoring. The entire process does not require manual operation or personnel to conduct insulation testing on site. Greatly reduces the risk of equipment failure and ensures the safety of operators.

4. Realize remote monitoring, centralized monitoring, and real-time monitoring

For cranes used in complex environments such as mines, construction sites, ports, offshore platforms, etc., monitoring the insulation resistance of the crane requires a complex workflow and heavy workload. The SKIM24-3C intelligent insulation monitoring device not only comes with an LCD screen display for local display, but also can rely on RS485 communication for remote office monitoring. If multiple cranes are working simultaneously, Sikcon's insulation monitoring and control system can be relied upon for centralized management, and connected to the entire internal information system of the enterprise through communication technology or other information links.

5. Features of SKIM24-3C Intelligent Insulation Monitoring Device for Cranes

● Insulation resistance detection for crane motors with voltage below 1140V

● Three independent measurements of ground insulation resistance.

● Three independent relay alarm outputs.

● Equipped with remote testing and reset functions.

● LCD screen display with backlight, allowing for viewing and setting various parameters.

● RS-485 interface communication, using Modbus protocol.

● The measurement process is fully automated and can also be manually initiated.

● Test voltage DC24V.

3. Automatic monitoring, reducing equipment failure risks, and ensuring personnel safety

SKIM24-3 intelligent insulation monitoring device can perform automatic monitoring according to the power status. When the power is turned off, the intelligent insulation monitoring device automatically starts to monitor the insulation resistance; When the power is turned on, the insulation monitoring device will automatically stop insulation monitoring. The entire process does not require manual operation or personnel to conduct insulation testing on site. Greatly reduces the risk of equipment failure and ensures the safety of operators.

4. Realize remote monitoring, centralized monitoring, and real-time monitoring

For cranes used in complex environments such as mines, construction sites, ports, offshore platforms, etc., monitoring the insulation resistance of the crane requires a complex workflow and heavy workload. The SKIM24-3C intelligent insulation monitoring device not only comes with an LCD screen display for local display, but also can rely on RS485 communication for remote office monitoring. If multiple cranes are working simultaneously, Sikcon's insulation monitoring and control system can be relied upon for centralized management, and connected to the entire internal information system of the enterprise through communication technology or other information links.

5. Features of SKIM24-3C Intelligent Insulation Monitoring Device for Cranes

● Insulation resistance detection for crane motors with voltage below 1140V

● Three independent measurements of ground insulation resistance.

● Three independent relay alarm outputs.

● Equipped with remote testing and reset functions.

● LCD screen display with backlight, allowing for viewing and setting various parameters.

● RS-485 interface communication, using Modbus protocol.

● The measurement process is fully automated and can also be manually initiated.

● Test voltage DC24V.